Yueqing, China, \[2025.10.15] – Within the broad application spectrum of micro switches, products capable of handling higher currents remain the backbone for driving the stable operation of industrial equipment and major home appliances. Recently, Wenzhou Tongda Electric Co., Ltd. in Yueqing announced that its 16A micro switch series, one of its core product lines, has become a significant engine for the company's business growth. Leveraging exceptional electrical performance and reliability, it has secured a broad customer base in the highly competitive market.

Precise Positioning: Overcoming Technical Barriers in High-Current Applications

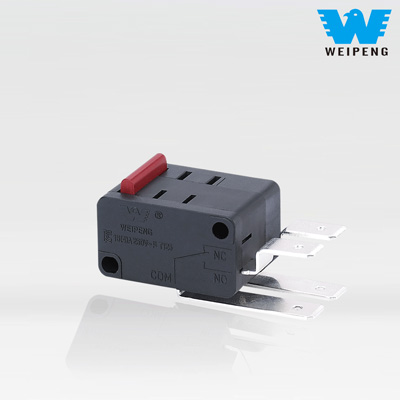

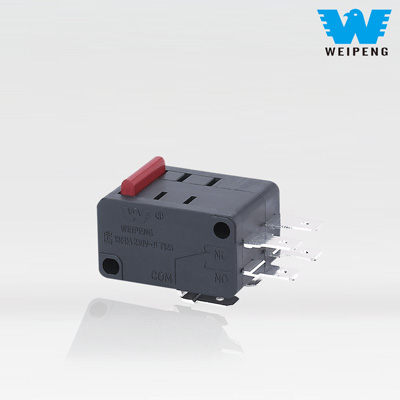

Unlike standard low-current signal switching micro switches, 16A micro switches are designed to safely and stably control high-load devices such as motors, compressors, and high-power heating elements. This places near-stringent demands on the switch's contact materials, arc quenching capability, heat dissipation design, and mechanical structure.

Building on its profound industrial experience accumulated in Yueqing, known as the "Capital of Electrical Equipment," Wenzhou Tongda Electric identified high-capacity 16A micro switches early on as a key focus for technological breakthrough and market development. The company's Technical Manager stated, "The 16A rating is a critical technical threshold. It signifies that our products must withstand the arc impact generated during frequent switching, ensure contact resistance remains low throughout the product's entire lifecycle, and thereby prevent safety hazards caused by overheating."

Precision Manufacturing: Forging Stable and Reliable Product Quality

To achieve this goal, Tongda Electric has dedicated extensive effort to the manufacturing of its 16A micro switches. Primarily, for the core contact materials, options like silver tin oxide with superior anti-weld properties are selected, significantly enhancing the contacts' resistance to arc erosion when switching high currents. Furthermore, the switch housing utilizes flame-retardant engineering plastics, and the internal arc quenching structure is optimized, effectively improving the product's safety rating.

At the end of the production line, every single 16A micro switch must pass multiple quality checkpoints, including full-load (16A) switching endurance tests, high-temperature and high-humidity environmental tests, and dielectric strength tests. "We simulate conditions harsher than actual operating environments," the Quality Director emphasized. "Only products that remain stable after thousands of full-load switching cycles qualify for delivery to our customers. This is a non-negotiable requirement for our products."

Market Application: Deeply Serving Core Industrial and Appliance Sectors

Thanks to their robust quality, Tongda Electric's 16A micro switches have successfully penetrated several core application areas. In industrial control, they are widely used in AC contactors, relays, CNC equipment, etc., serving as reliable units for signal transmission and status detection. In the home appliance sector, they have become indispensable control and protection components in products like high-power washing machines, air conditioners, and commercial kitchen appliances.

The company's Sales and Marketing Director commented, "When customers choose our 16A switches, they are essentially choosing a commitment to safety and performance. We not only provide standard products but also offer customization services based on clients' specific installation space and circuit requirements. This has created a unique competitive advantage for us against international brands."

Future Outlook: Continuously Consolidating Leadership in Power Switching

Looking ahead, the market demand for highly reliable, long-life 16A micro switches is expected to remain strong, fueled by industrial automation upgrades and the proliferation of smart appliances. Wenzhou Tongda Electric Co., Ltd. announced that it will continue to increase R\&D investment in high-load micro switches, striving for new breakthroughs in materials science and structural design to further enhance product electrical life and environmental adaptability. The company aims to establish itself as the preferred partner for global customers in the field of high-quality micro switch solutions.