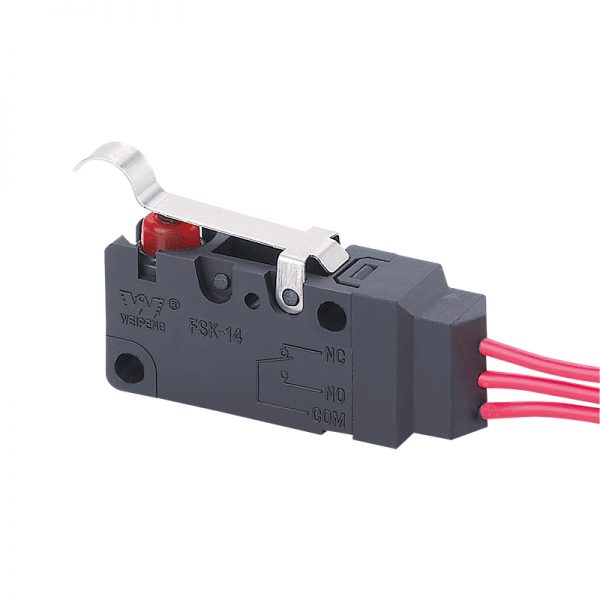

Micro Switch No: Enabling Precise Triggering and Safety Control

In smart home sensing, industrial equipment limit control, and security alarm systems, Micro Switch No serves as the "key to trigger response", and its on-off sensitivity directly affects equipment start-stop and safety early warning. Yueqing Tongda Wired Electric Factory, which has been deeply engaged in the switch field for more than 30 years, focuses on the specialized R\&D of Micro Switch No. It solves the pain points of traditional products such as "trigger delay and poor environmental resistance", providing stable and reliable control solutions for multiple industries.

Yueqing Tongda lists Micro Switch No as a core main product, driven by in-depth insights into industry needs. Traditional normally open micro switches often suffer from poor contact and trigger stroke deviation, leading to sensing failure of smart door locks and misjudgment of industrial machinery limits. To address this, the R\&D team has made targeted optimizations: the contacts are made of silver-palladium alloy and processed through vacuum coating technology to reduce contact resistance, controlling the trigger response time within 0.02 seconds; an innovative "micro dual-spring structure" is adopted, and the trigger stroke error is reduced to ±0.05mm through laser calibration, meeting the control needs of precision equipment. Meanwhile, the shell is made of flame-retardant PA66 material, reaching IP65 protection level, which can work stably in environments ranging from -40℃ to 85℃.

Scenario-based customization enhances the product's competitiveness. For the smart home field, a "low-power model" is launched with a standby power consumption as low as 3μA, meeting the long battery life needs of wireless sensing devices; for the industrial field, a "shock-resistant model" is developed, using a zinc alloy base that can withstand high-frequency vibrations of 1000Hz, suitable for machine tool limit control; the special model for security systems strengthens trigger stability, allowing quick circuit closure with a slight external force, and its response speed is 30% faster than traditional products. Previously, the Micro Switch No customized for a smart security enterprise helped reduce the false alarm rate of its alarm system by 50%, securing a long-term cooperation order.

Quality control runs through the entire production process. In the raw material link, each batch of silver-palladium alloy contacts must pass spectral testing; in the production link, fully automated assembly equipment ensures that the component error is ≤ 0.01mm; in the finished product link, each switch must undergo 100,000 pressing tests and high-low temperature cycle tests, with a qualification rate of 100%. Currently, the product has passed UL and CQC certifications and become a qualified supplier for enterprises such as Midea and Haier, continuously empowering safety control in multiple scenarios.

Share to: